TECHNOLOGY AND QUALITY CULTIVaTED OVER 100 YEARS OF HISTORY

FAST IGNITION

It ignites faster than Bincho charcoal or Oga charcoal, eliminating the hassle and waiting time for starting a fire.

BURNS LONGER

High heating power and far infrared rays effect, and the ingredients are baked well.

LESS SPARK & SMOKELESS

The charcoal is easy to handle because there is little so-called "explosion" where the charcoal bursts suddenly.

Since there is almost no smoke or odor, it does not interfere with cooking or spoil the original aroma of the ingredients.

KUROSUMI Japanese Charcoal Prime Minister Award winning

Dedication to our roots is the reason our charcoal artisans win top prizes in Japan, such as KUROSUMI receiving the first Prime Minister’s Award to recognize achievements in charcoal technology in 2018.One of our charcoal craftsmen has also won the highest award for charcoal in Japan. They’re a veritable charcoal expert who mentors apprentices and judges competitions.

ABOUT PRODUCTION AREA

Iwate Prefecture has produced charcoal for over a thousand years.Founded in 1916, Yachiringyo Co., Ltd. is now the largest charcoal producer in Iwate Prefecture and we still use traditional manufacturing methods to produce high-quality charcoals.

"Iwate Nature and waterfalls" © Soya_F (Licensed under CC BY 4.0)

In Kuji City, Iwate Prefecture, one of Japan's leading charcoal production areas, we consistently handle everything from growing raw wood to logging and charcoal production. The oak tree has a particularly excellent regenerative ability, and if it is cut down in a certain cycle, it will sprout new shoots and will be reborn as a healthy forest in 20 to 25 years. Producing charcoal in Iwate and having people use it helps nurture and protect Iwate's forests.

ABOUT CHARCOAL MAKING

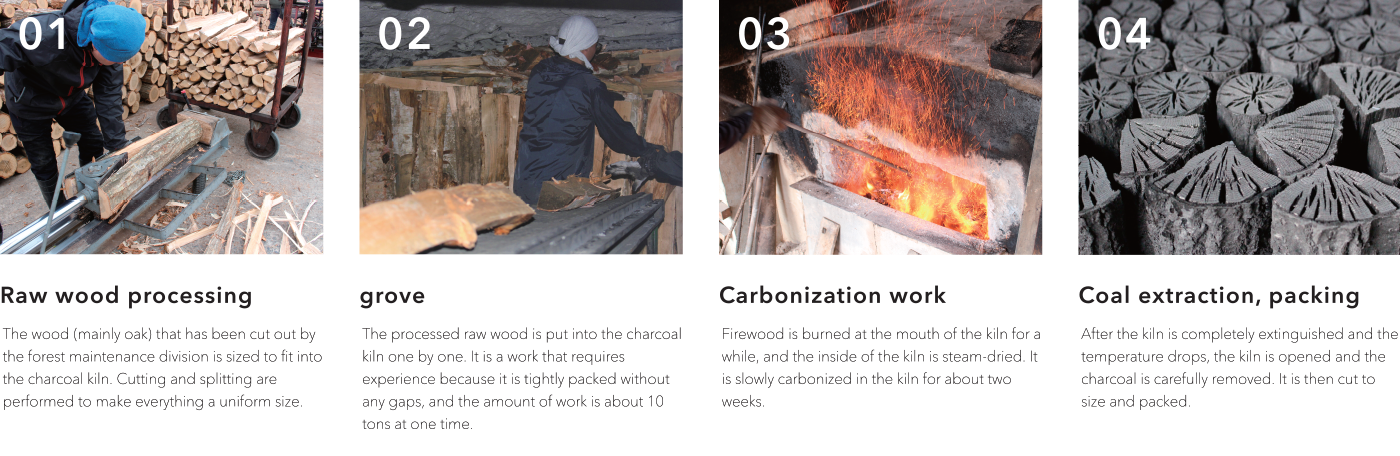

Raw wood processing

The wood (mainly oak) that has been cut out by the forest maintenance division is sized to fit into the charcoal kiln. Cutting and splitting are performed to make everything a uniform size.

grove

The processed raw wood is put into the charcoal kiln one by one. It is a work that requires experience because it is tightly packed without any gaps, and the amount of work is about 10 tons at one time.

Carbonization work

Firewood is burned at the mouth of the kiln for a while, and the inside of the kiln is steam-dried. It is slowly carbonized in the kiln for about two weeks.

Coal extraction, packing

After the kiln is completely extinguished and the temperature drops, the kiln is opened and the charcoal is carefully removed. It is then cut to size and packed.

ABOUT CHARCOAL BURNING OF YACHIRINGYO Co.,Ltd